CRUSH DOWNTIME.

NOT YOUR TARGETS.

AI.Downtime gives you the root cause, the real-time data, and the game plan to slash downtime by up to 40%. It's time to stop reacting and start dominating your production goals.

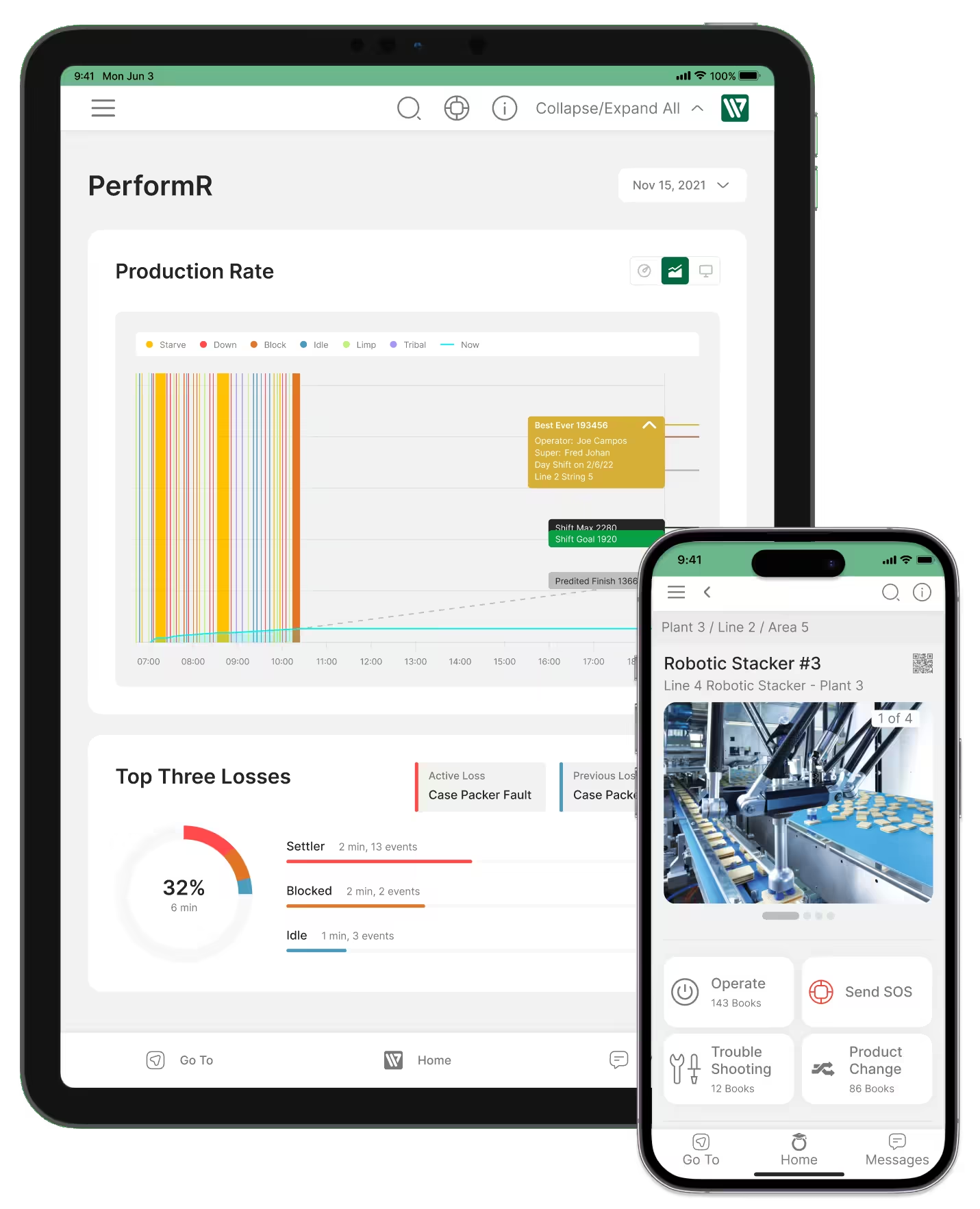

No dashboards to learn. No reports to pull. Just ask a question in plain English and Ai.Downtime delivers the answer — backed by real machine data.

Downtime is your most expensive line item — and the hardest to see.

Every minute of stoppage = lost revenue, missed shipments, and frustrated teams.

Up to 20% of capacity is lost to downtime in most plants.

Most companies can't pinpoint the "why" — so the same losses repeat.

Turn downtime into ROI.

40% reduction in unplanned downtime.

Top 3 causes identified in 30 days.

5–10x ROI in year one.

Sustainable fixes that stick.

Real plants. Real ROI.

Potato processing plant reduced downtime by 45%, saving over $1.2 million annually through predictive maintenance.

Packaging facility identified conveyor bottlenecks, increasing throughput by 18% and reducing overtime costs.

Food manufacturing plant achieved 300% ROI in the first year through reduced waste and improved efficiency.

Your path to ROI is simple.

Book a 15-min Call

Discuss your current challenges and goals with our experts.

Get a Custom ROI Projection

Receive a personalized analysis of your potential savings and timeline.

Deploy Quickly, See Results in Weeks

Implementation takes just weeks, with measurable improvements starting immediately.

"AI.Downtime paid for itself in the first quarter — everything after that is profit."

Downtime is already costing you. Don't keep paying for it.

AI.Downtime turns your losses into measurable gains.

Book a Discovery Call

Unlock Your Team's Full Potential

Put your know-how in everyone's hands; how would your business do if every team member performed like your best?