CRUSH DOWNTIME.

NOT YOUR TARGETS.

AI.Downtime gives you the root cause, the real-time data, and the game plan to slash downtime by up to 40%. It's time to stop reacting and start dominating your production goals.

Built for production & packaging operations

Most Downtime Systems Create Visibility. Not Answers.

Dropdown menus, operator logs, and spreadsheet trackers create the illusion of downtime management. But they rely on opinions, delayed reporting, and incomplete data — leaving your team chasing symptoms instead of causes.

From Opinions to Evidence. From Guesswork to Precision.

A Structured Path From Downtime Data to Lasting Gains

Not just software — a proven, built-in approach that turns every fault event into a step toward operational excellence.

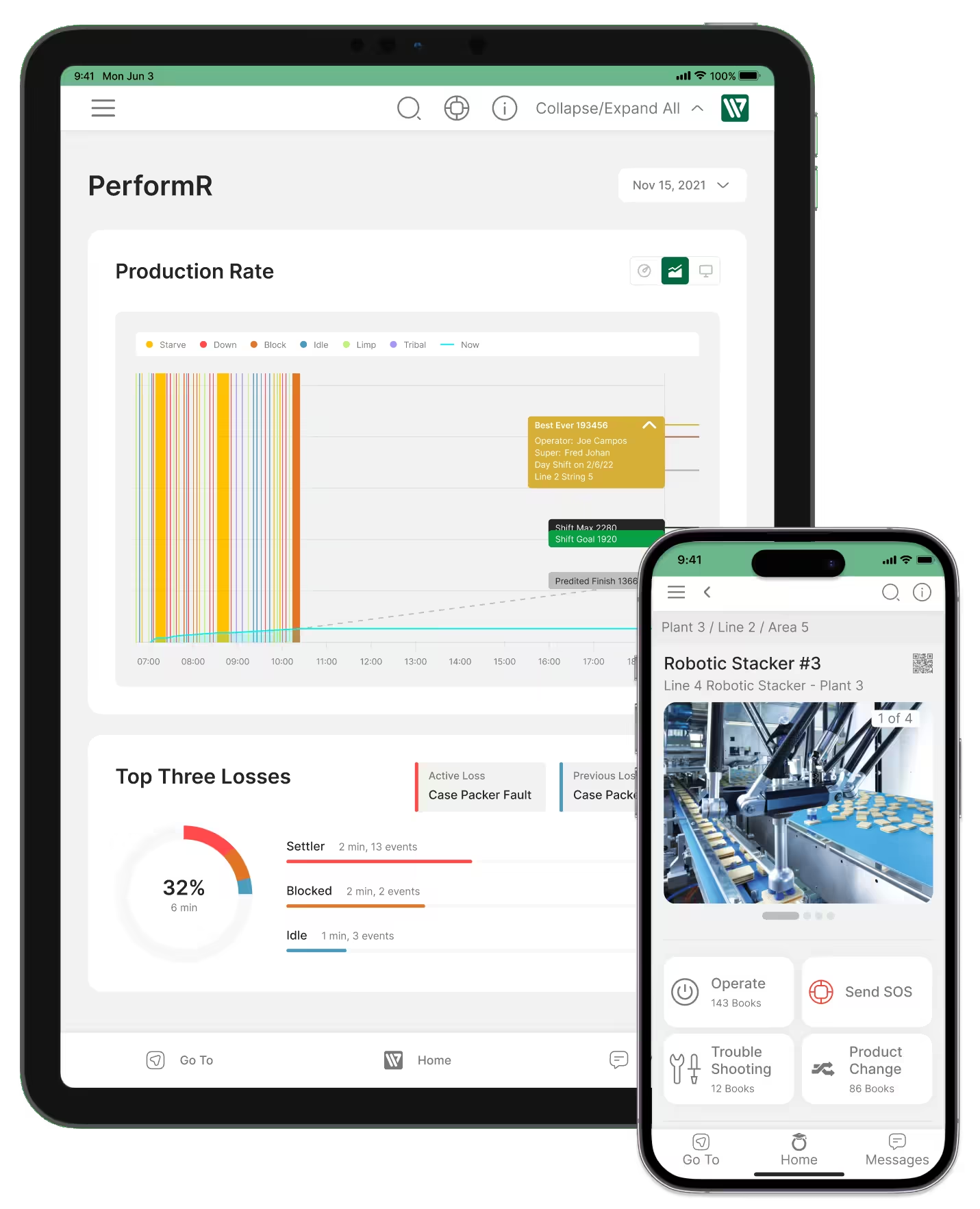

Everything Your Team Needs to Own Uptime

From real-time diagnostics to predictive intelligence, Ai.Downtime gives every role in your operation the insight to act — immediately.

for data collection

capture precision

from equipment

anywhere, any device

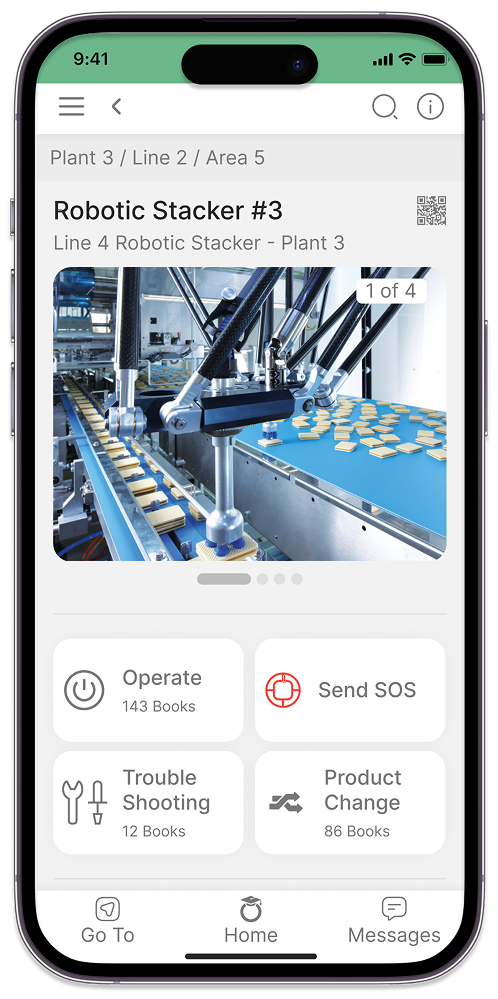

Ai.Downtime Finds the Problem. bOpus Helps Your Team Fix It.

Every Ai.Downtime customer gets bOpus — the knowledge platform that puts step-by-step troubleshooting guides, SOPs, and rich-media walkthroughs directly in your operators' and technicians' hands, right where work happens.

Built for Production. Proven Across Verticals.

Any production or packaging operation where uptime drives margins and predictability matters.

Works With What You Have. No Rip-and-Replace.

Ai.Downtime connects to your existing infrastructure — from the machine level up. Secure cloud platform with full encryption, globally accessible, and no local IT burden.

Most systems rely on operator input or higher-level software. Ai.Downtime goes straight to the equipment for sub-second fault data — the fastest, most accurate source of truth.

We stopped arguing about what was causing downtime. The system showed us. Within two weeks we'd eliminated our number one loss — and the fix was something we'd walked past for months.

— Plant Manager, Food & Beverage

Ready to See Exactly Where Your Lines Are Losing Money — and How to Stop It?

Request a demo and see how Ai.Downtime identifies, fixes, and eliminates downtime across your production and packaging operations — with bOpus built right in.

Your path to ROI is simple.

Book a 15-min Call

Discuss your current challenges and goals with our experts.

Get a Custom ROI Projection

Receive a personalized analysis of your potential savings and timeline.

Deploy Quickly, See Results in Weeks

Implementation takes just weeks, with measurable improvements starting immediately.

"AI.Downtime paid for itself in the first quarter — everything after that is profit."

Downtime is already costing you. Don't keep paying for it.

AI.Downtime turns your losses into measurable gains.

Book a Discovery Call

Unlock Your Team's Full Potential

Put your know-how in everyone's hands; how would your business do if every team member performed like your best?