CRUSH DOWNTIME.

NOT YOUR TARGETS.

AI.Downtime gives you the root cause, the real-time data, and the game plan to slash downtime by up to 40%. It's time to stop reacting and start dominating your production goals.

Downtime Is More Expensive

Than You Think

Every minute of unplanned downtime triggers a chain reaction across your operation. It's not just the line that stops — it's the overtime to catch up, the scrapped product, the missed shipment, the emergency parts order, and the customer call you don't want to make.

Most plants know downtime is expensive. Very few know exactly how expensive — because the true cost is buried across departments, budgets, and workarounds that have become so routine no one questions them anymore.

The longer downtime goes unmeasured and unattributed, the more your team accepts it as the cost of doing business. It isn't. It's the cost of not having the right data.

- Lost throughput$12,500/hr

- Scrap & rework$3,200/hr

- Labor waste$2,800/hr

- Emergency response$1,500/hr

Why Most Downtime Solutions Fail

You've tried tracking downtime before. Here's why it didn't work — and why it's not your fault.

Operator-Dependent Data

Operators code downtime from memory at the end of a shift. By then the details are gone, the context is lost, and the data is wrong.

Cascading Faults Look Like Root Causes

When Machine A faults and causes Machine B to stop, most systems blame Machine B. Your team fixes the wrong thing, and the problem comes right back.

Activity Without Accountability

Reports get generated. Meetings get held. But without machine-level root cause data, decisions are based on opinions — not evidence.

From Guesswork to Precision

Every differentiator is a direct answer to why other approaches fail.

Data Captured Directly From Your Equipment

Fault events are recorded with sub-second precision straight from PLCs and controllers. No operator logging, no dropdown menus, no shift-end guesswork. The data is accurate because humans never touch it.

AI Traces Fault Chains to the Source

When cascading faults hit, Ai.Downtime uses precise timing data and machine learning to identify the initiating fault — not the most visible symptom. Your team fixes the right thing the first time.

Every Fix Is Tracked and Measured

Corrective actions feed back into the system. You see whether each fix actually reduced downtime or not. No more recurring problems disguised as new ones. Your operation gets smarter with every event.

We stopped arguing about what was causing downtime. The system showed us. Within two weeks we'd eliminated our number one loss — and the fix was something we'd walked past for months.

downtime in 90 days

See Exactly Where Your Lines

Are Losing Money

Book a 15-minute call. We'll show you what Ai.Downtime can do for your operation.

Book a 15-min Call

Discuss your current challenges and goals.

Get a Custom ROI Projection

A personalized analysis of your potential savings.

Deploy & See Results in Weeks

Measurable improvements from day one.

Your path to ROI is simple.

Book a 15-min Call

Discuss your current challenges and goals with our experts.

Get a Custom ROI Projection

Receive a personalized analysis of your potential savings and timeline.

Deploy Quickly, See Results in Weeks

Implementation takes just weeks, with measurable improvements starting immediately.

"AI.Downtime paid for itself in the first quarter — everything after that is profit."

Downtime is already costing you. Don't keep paying for it.

AI.Downtime turns your losses into measurable gains.

Book a Discovery Call

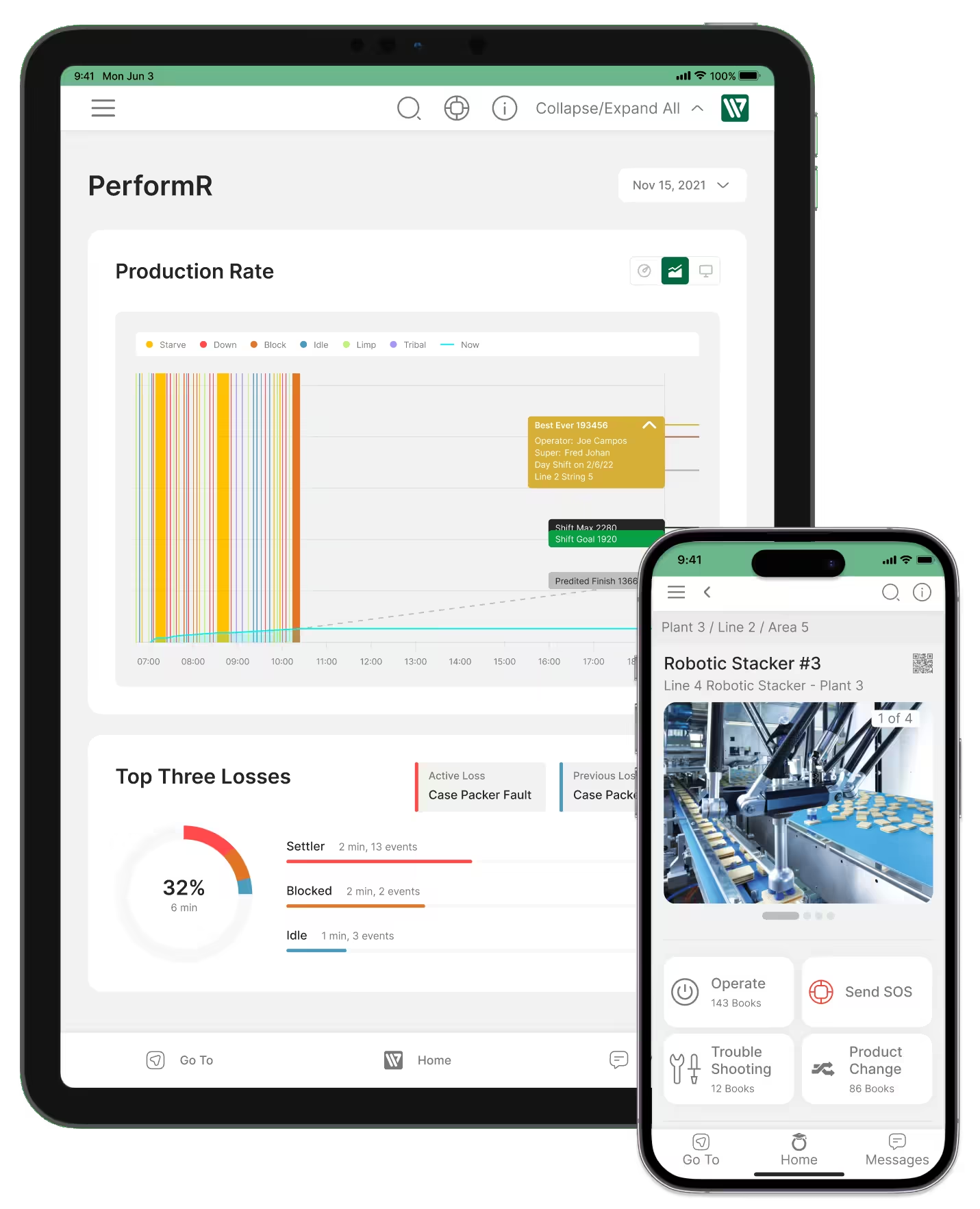

Unlock Your Team's Full Potential

Put your know-how in everyone's hands; how would your business do if every team member performed like your best?