TURN DOWNTIME INTO YOUR NEXT ENGAGEMENT.

Ai.Downtime doesn't replace your services — it supercharges them. Every deployment means integration revenue upfront, a continuous pipeline of improvement projects, and a seat at the table as your customer's most trusted partner.

Trusted across manufacturing verticals

Your Customers Are Already Losing Money to Downtime. They Just Don't Know Where.

Right now your customers troubleshoot with gut feel, tribal knowledge, and spreadsheets. They know downtime costs them — but they can't tell you exactly which machine, which fault, or which shift is bleeding the most money. Ai.Downtime changes that. And when the data reveals what's broken, who do they call? You.

Three Revenue Streams. One Platform.

Ai.Downtime creates immediate integration revenue and a self-generating pipeline of follow-on services work — all while making you indispensable to your customer.

Integration & Deployment Revenue

Every Ai.Downtime system requires integration help — PLC connections, sensor mapping, historian tie-ins, MES integration. That work is yours from day one.

- → PLC and controller connectivity

- → Sensor and I/O mapping

- → Historian and MES integration

- → Network and infrastructure setup

- → Commissioning and validation

Continuous Improvement Projects

Once the system is live, Ai.Downtime surfaces exactly where the automation and controls need attention. That work goes to the integrator — you.

- → Root cause reveals automation gaps

- → Control logic optimization projects

- → HMI and SCADA improvements

- → Line balancing and changeover work

- → Predictive maintenance programs

Trusted Partner Relationship

You're no longer waiting for the phone to ring. You're proactively showing customers what needs to happen next — with the data to prove it.

- → Quarterly performance reviews

- → Capital project justification with data

- → Multi-line and multi-site rollouts

- → Long-term retainer engagements

- → Expansion into new plant areas

From Deployment to Ongoing Revenue in Four Steps

You Deploy

Integrate Ai.Downtime with the customer's PLCs, sensors, and control systems. Billable integration services from day one.

Data Reveals Truth

Sub-second fault capture, root cause identification, and AI analytics expose the real sources of downtime — no guessing.

You Fix It

The data points directly to what needs engineering attention — controls upgrades, automation gaps, line rebalancing. All billable work for you.

Repeat & Expand

Proven ROI on one line leads to rollout across the plant — and then across the enterprise. Your engagement grows with results.

integrator services

revenue vs. initial deployment

to additional lines

for data collection

Stop Waiting for the Phone to Ring. Start Creating Demand.

Ai.Downtime doesn't compete with your services. It creates an ever-expanding need for them.

Data Creates Demand

When customers see exactly where they're losing money, they don't ask "if" they should invest — they ask "how fast can you start?"

You Become the Trusted Advisor

Instead of competing on price for one-off projects, you're the proactive partner who brings insights and recommendations backed by data. That changes the relationship entirely.

Every Fix Reveals the Next Opportunity

Fix the top loss, and the second-biggest loss becomes visible. Optimize one line, and the customer wants the rest. The work compounds.

Prove Your Impact With Hard Numbers

No more subjective assessments. Ai.Downtime tracks before/after performance so you can show exactly what your work delivered — the best case for more investment.

A Complete Solution, Delivered Through You

Every Ai.Downtime deployment includes bOpus — the knowledge platform that puts step-by-step troubleshooting guides directly in your customer's operators' hands.

AI-Driven Root Cause in Minutes

Sub-second fault timing, cascading fault identification, and machine learning that distinguishes the initiating fault from the symptoms. No operator input required.

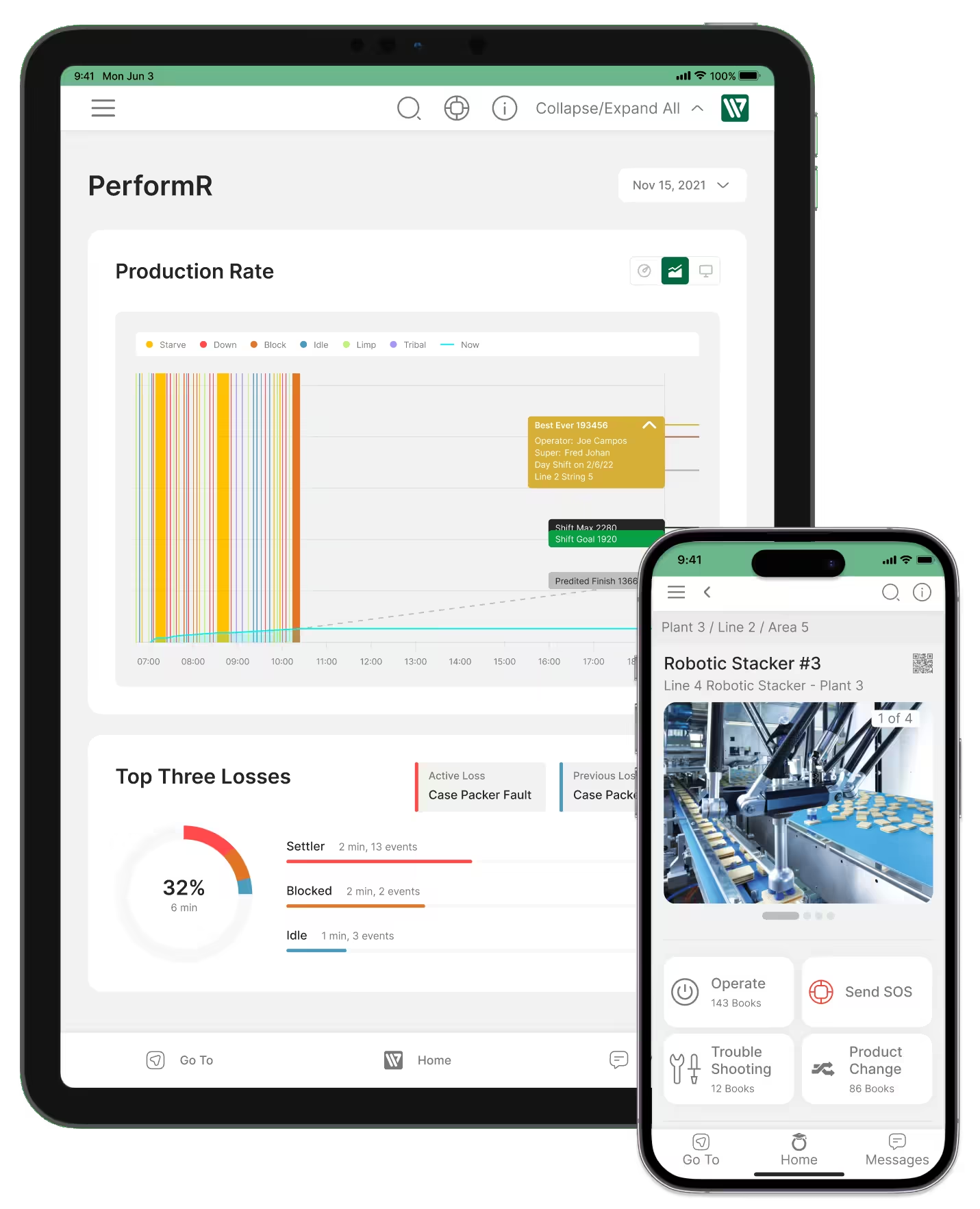

bOpus Knowledge at Point of Need

When Ai.Downtime flags an issue, bOpus delivers the right SOP or troubleshooting guide — with video, photos, and step-by-step walkthroughs — right to the operator's device.

Real-Time OEE Dashboards

Role-specific views for operators, supervisors, and plant managers. Top losses, trends, root causes, and gains visualized in real time so decisions happen immediately.

Predictive Maintenance Intelligence

Machine learning identifies patterns before failures happen, shifting your customer from reactive firefighting to planned, preventive maintenance — fewer emergencies, more uptime.

"The best part isn't the data — it's that I don't have to convince my customer they have a problem anymore. The system shows them. Then they ask me to fix it."

— Systems Integrator, Food & Beverage

Ready to Add a Recurring Revenue Engine to Your Integration Business?

Let's talk about how Ai.Downtime can generate integration services revenue, create a continuous project pipeline, and position you as the indispensable partner your customers can't afford to lose.